Spline Bushings

Since 1978, WLY transmission has been manufacturing hydraulic components, including spline shafts and bushings. We can repair hydraulic pumps, motors and valves, as well as overhaul barrels, paddles, pressure plates and oval rings. We distribute a number of internationally recognized brands in order to provide our customers with high-quality products.

Company Profile

WLY transmission was established in 1988 and has many years of experience in designing and manufacturing drive shafts, cardan shafts, steering shafts, and power output shafts. Not only we also provide various spare parts for industrial, automotive and agricultural machinery.

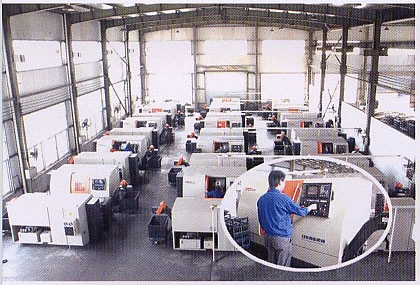

Our factory has strong technical force, sophisticated equipment and perfect testing methods to ensure product quality. We have obtained the ISO/TS 16949:2009 certificate.Can provide services including design, development, testing and transportation.We are happy to serve a diverse number of wholesalers, traders, factories and OE buyers around the world.

For more information, please contact us directly.

Function of bushing

Spline Bushing has high flexibility and can play many roles. Generally speaking, bushing is a kind of component to protect equipment. The use of bushing can reduce the wear, vibration and noise of equipment, and has anti-corrosion effect. The use of bushing can also facilitate the maintenance of mechanical equipment and simplify the structure and manufacturing process of equipment.

Bushing Material

The material of the bushing is mostly soft metal, rubber, nylon and non-metallic polymers. The texture of these materials is relatively soft. The bushing can withstand vibration, friction and corrosion to protect the wrapped parts, and the bushing itself is replaced after damage Convenience, low cost and good economy.

Company Blog

Good quality

Are there spline bushings designed for use in applications with high axial loads? Yes, there are spline bushings specifically designed to handle high axial loads in various applications. These bushings are engineered with features and materials that can withstand the...

Good quality

Can I get recommendations for spline bushings suitable for high-speed rotational applications? When it comes to high-speed rotational applications, it is crucial to select spline bushings that can withstand the demanding conditions and provide reliable performance....

Hot selling

Are there spline bushings designed for use in applications with high axial loads? Yes, there are spline bushings specifically designed to handle high axial loads in various applications. These bushings are engineered with features and materials that can withstand the...